In the mining industry, Mine Useful Life (LoM) refers to the anticipated duration of a mining project, from the initial exploration phases to closure and post-closure. A crucial aspect for the effective management of LoM is the management of tailings, the by-products generated after the extraction of the valuable ore. This article explores how mining operations, especially as it relates to tailings management, align with best practices, with a focus on the Global Industry Standard on Tailings Management (GISTM). Implementing effective tailings management, guided by GISTM, ensures environmental sustainability and community safety throughout the entire life cycle of the mine.

Understanding Mine Life (LoM)

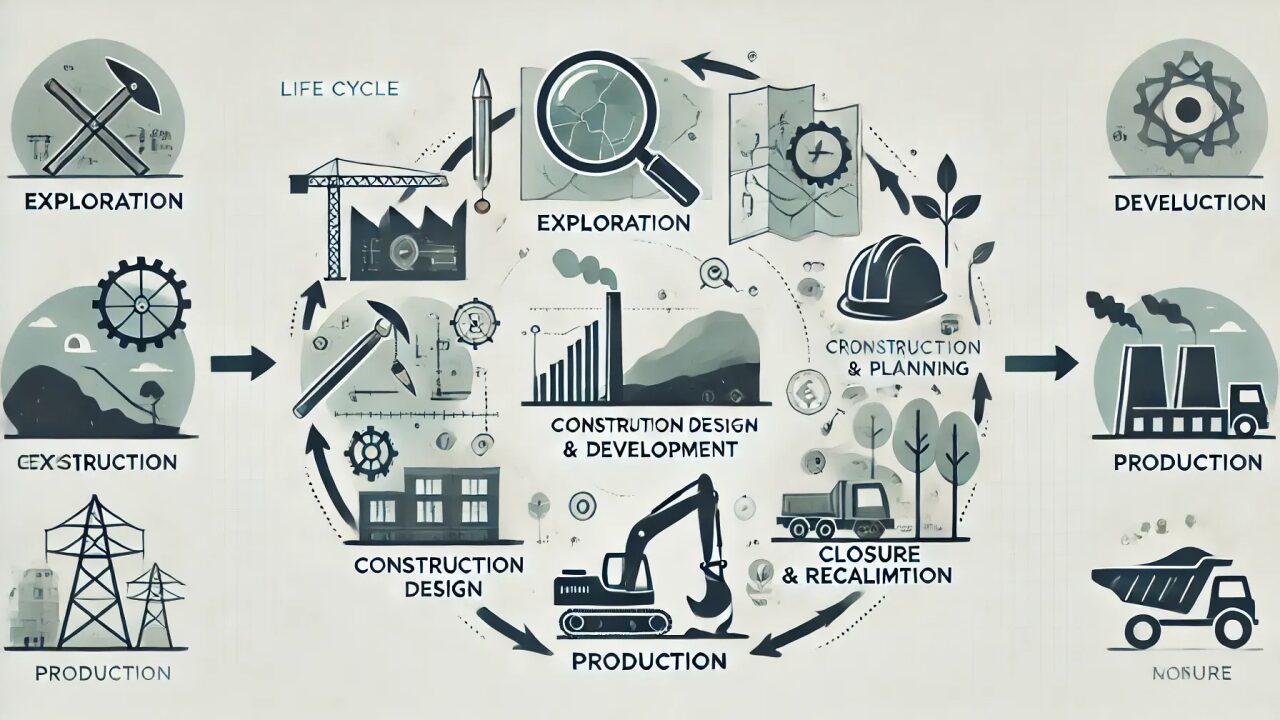

LoM defines all stages of a mining operation, including exploration, design, development, extraction, tailings storage, and closure. Each phase requires careful planning, management, and compliance with standards that meet Environmental, Social, and Governance (ESG) responsibilities.

Key industry guidelines, including those published by the International Council on Mining and Metals (ICMM), provide comprehensive frameworks to ensure sustainable development. These include the Mining Principles, the Good Practice Guide in Tailings Management and the Global Industry Standard on Tailings Management (GISTM), which help operators mitigate the risks associated with tailings throughout the LoM.

Global Industry Standard on Tailings Management (GISTM)

The GISTM, developed by ICMM, UNEP and PRI, sets the highest standard for tailings facility management, with the goal of achieving zero harm to people and the environment throughout the entire life cycle of the tailings facility. The GISTM framework is designed to be flexible yet robust, allowing operators to tailor it to their specific legal, operational, and contextual requirements.

Key elements of GISTM:

- Respect for affected communities:

GISTM highlights the importance of engaging with affected communities. Mining companies must respect the rights of communities impacted by their operations, actively involve them in the decision-making process, and keep communication channels open throughout the life cycle of the tailings facility, to effectively manage social and environmental impacts. - Integrated knowledge base:

One of the core principles of GISTM is the development of a comprehensive interdisciplinary knowledge base, which covers social, environmental, economic, and technical aspects of tailings management. This knowledge is essential for making informed decisions about tailings throughout the facility’s lifecycle. - Design, construction, operation and monitoring:

GISTM provides specific requirements for designing, constructing and operating tailings facilities in a way that minimizes risks at each stage. It emphasizes the importance of continuous monitoring, risk assessment, and adaptive management techniques, especially to address challenges such as climate change and material variability. Effective water management systems are also essential to ensure long-term sustainability. - Governance and accountability:

Proper governance is essential for maintaining the integrity of tailings facilities. The GISTM requires mining companies to appoint executives responsible for tailings management, with clear review and assurance systems in place. Independent review bodies, such as the Independent Tailings Review Board (ITRB), play a key role in assessing and validating the safety and performance of tailings facilities throughout their life cycle. - Emergency preparedness and long-term recovery:

The standard also requires mining companies to have emergency response plans, designed to reduce the risks of tailings facility failure and support long-term recovery efforts should an event occur. Plans should include clear protocols for engaging local authorities and communities in preparedness activities.

Mine Life Tailings Management (LoM)

Tailings management is not an isolated task, but must be integrated into the wider mine planning process. A holistic approach to the tailings management lifecycle ensures that facilities are designed, constructed, and managed safely and sustainably from conception to post-closure.

Main stages of tailings management at LoM:

- Planning and design (pre-conception and design phases):

Initial planning is critical for selecting optimal locations for tailings storage and designing facilities that can accommodate future risks, such as climate change. Decisions made at this stage have a major impact on the safety and long-term environmental outcomes of the tailings facility. - Operations and Ongoing Construction:

During the operational phase, continuous monitoring, water management, and updating safety protocols ensure that tailings facilities remain functional and safe. Adaptive management techniques, including real-time monitoring, are essential to minimize the risks associated with tailings management. - Closure and post-closure:

Planning for mine closure, including the decommissioning of tailings facilities, should begin early in the mine lifecycle. The closure phase focuses on the rehabilitation and maintenance of tailings facilities to prevent environmental degradation. After closing, continuous surveillance and maintenance are required to ensure the stability and integrity of the facility over time.

Conclusion

Effective tailings management, guided by the principles of the Global Industry Standard on Tailings Management (GISTM), is critical to the sustainability of mining operations throughout the Life of the Mine. By incorporating robust governance, technical excellence, and community engagement into each phase of the mine lifecycle, companies can ensure the safety of their facilities and the protection of people and the environment.

Mining companies are encouraged to integrate GISTM into their operations, prioritizing responsible tailings management to ensure the long-term sustainability of the industry and the communities it serves.